Adaptive AI for Additive Manufacturing: Integrity Layer by Layer

Reduce surface defects, adapt to new alloys faster, and unlock real-time control — without changing your machines.

What Ailoys Does

Ailoys doesn't just monitor your machines — it understands them.

Here's how it brings real-time intelligence to your additive manufacturing environment:

Here's how it brings real-time intelligence to your additive manufacturing environment:

01

Machining Process Digital Twin

Proprietary sensing technology scans material microstructural changes in real time, synchronizing with controller data (feed, speed, spindle RPM) and existing NDT devices — acting as a hub for all available industrial data, with no MES dependency or manual entry.

02

Adaptive AI Twin

Builds a precise model of your optimal production cycle, flagging even subtle instabilities before they affect throughput or quality.

03

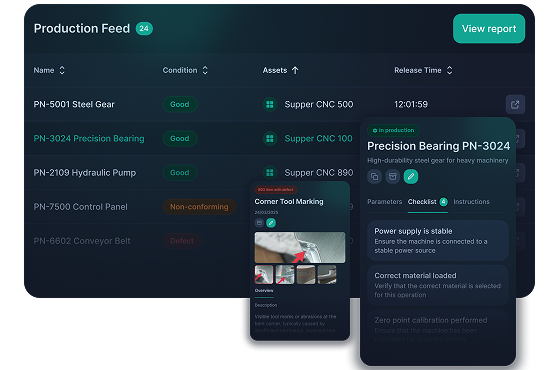

Operator-Friendly Guidance

Translates complex process analytics into clear, timely instructions that enable operators to take corrective action instantly.

04

Self-Improving QA Loop

Self adjusting feedback loop. Ailoys hub is able to interact with existing controllers, giving users flexibility in designing intelligent automatization with no code.

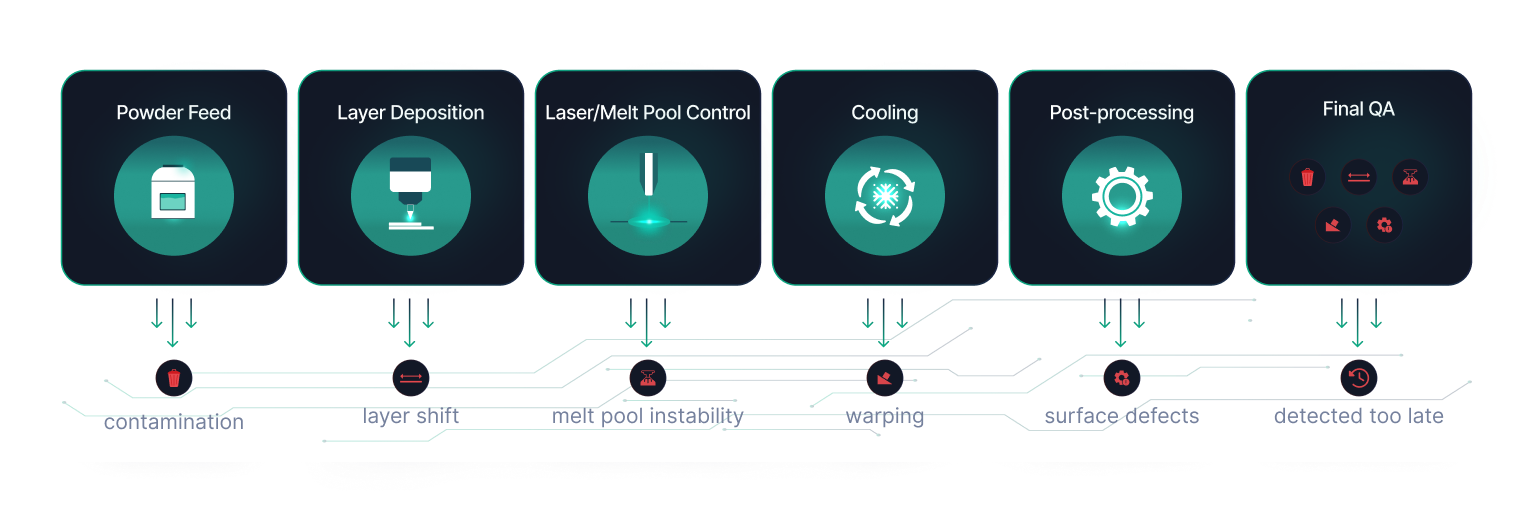

Why Additive Manufacturing Needs Real-Time Intelligence

Even the smallest instability in feed rate, laser power, or powder quality can cause costly part failures — often detected only after printing is complete. Ailoys brings real-time intelligence to every stage of additive manufacturing, ensuring stable processes and defect prevention before they escalate.

New Materials, New Challenges

Advanced alloys, composites, and high-temp polymers each behave differently under additive manufacturing conditions. Even minor variations can cause porosity or layer defects.

Complex Equipment, High Expectations

Multi-laser and multi-axis printers demand precise calibration. Without continuous monitoring, performance drift can go unnoticed until final inspection.

Hidden Defects, Visible Waste

Porosity, warping, or micro-cracks often remain undetected during printing and only become visible in post-process QA — increasing scrap rates and rework.

Operator Bottlenecks

Process expertise is scarce. Without AI, there's no consistent way to adjust parameters in real time for optimal results.

3 Core AI Solutions

for Manufacturing Excellence

Ailoys AI helps manufacturers overcome production challenges, optimize efficiency, and reduce errors. Discover how our key solutions transform industrial processes.

Solution #1

Digital Fingerprint

Solution #2

AI-Powered Quality Control

Solution #3

AI-Driven Process Optimization

Digital Fingerprint

AI analyzes sensor data and predicts potential equipment failures before they happen, preventing costly downtime.

- AI detects potential issues in advance

- Prevents unexpected shutdowns

- Maintenance happens only when necessary

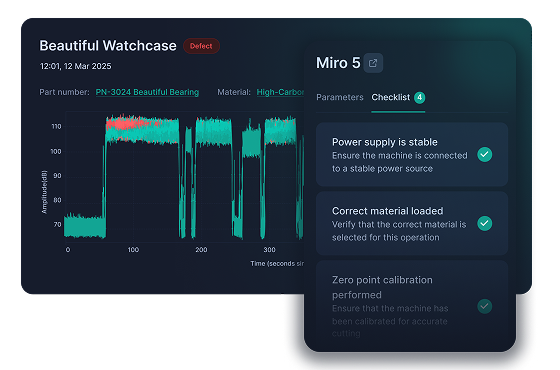

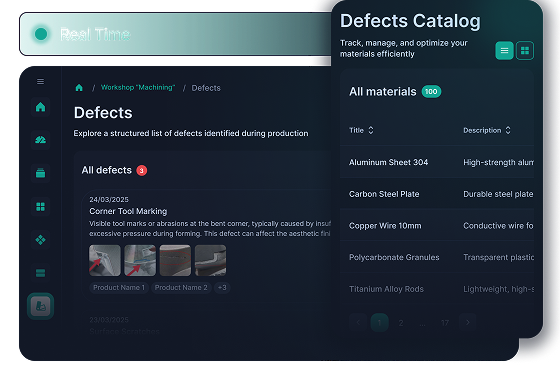

AI-Powered Quality Control

AI inspects products in real time, identifying defects faster than traditional quality control methods.

- Automated real-time product inspection

- Minimized rework and production losses

- Immediate defect reports for improved decision-making

AI-Driven Process Optimization

AI continuously analyzes manufacturing processes and suggests optimal adjustments for maximum efficiency.

- Optimized machine speed and performance

- Reduced energy consumption

- Improved production planning and scheduling

Sample Use Case

Use Case #4 — Additive Manufacturing: Aerospace

35% Faster Build Times. 50% Fewer Post-Processing Corrections.

In a metal additive manufacturing cell for aerospace components, thermal distortion and micro-porosity often led to rejected parts or extensive post-processing. Issues were typically identified only after printing completed, when defects were visible in CT scans or dimensional checks.

What Ailoys did

- Analyzed acoustic emissions and thermal signatures layer-by-layer

- Detected early indicators of porosity and layer misalignment

- Suggested laser power and scan path tweaks to fix deviations on the fly

Outcome

- Build times reduced by 35% through optimized layer parameters

- Post-processing corrections cut by 50%

- First-pass yield increased from 78% to 92%

Integration Made Simple

Description

Seamless Setup

No Machine

Fast Setup

Seamless Setup with Zero Downtime

Integrate without pausing production — our system installs alongside active lines, so data starts flowing from day one.

No Machine Modifications Needed

Use your machines as they are — no controller changes, no new PLCs. External sensors track vibration, torque, and temperature without disrupting operations.

Fast Setup, Cloud-Ready Dashboard

In just days, your digital fingerprint and analytics dashboard are online — no heavy IT lift required.

Go Live and Get Results in 3 Months

Ailoys doesn't just monitor your machines — it understands

them.

Here's how it brings real-time intelligence to your CNC environment:

Here's how it brings real-time intelligence to your CNC environment:

Step 1

Connect

Install 2–5 Ailoys units and sensors without stopping production. The setup is non-intrusive, so data is captured immediately while your lines keep running.

Step 2

Deploy AI

Stream acoustic, vibration, and torque data from Ailoys sensors to the cloud, building a unique digital fingerprint of your production process.

Step 3

Operate

Operators receive clear, plain-language live instructions to correct deviations before they impact quality — no complicated training required.

Step 4

Improve & Scale

The system refines recommendations after every cycle, adapting to your specific production patterns. Expands easily to other machines and lines.